ABOUT US

Over 35 years have passed since the outset of an adventure made of passion and continuous research in aluminum pressing for aerodynamic components used in race cars: this was the beginning of G&G Spoiler.

Since then, the passion and research have never ceased but have evolved and changed into craftsmanship and know-how, values that we offer our customers with our work, every day.

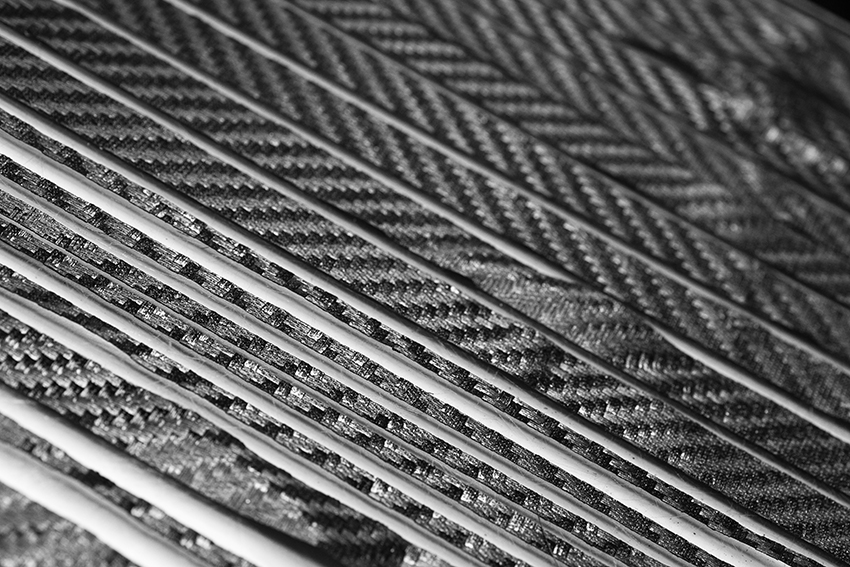

This tradition is well-preserved in today’s modern and efficient world in which G&G Spoiler becomes G&G Composites, leader in composite material processing.

PHILOSOPHY

Since its establishment, G&G has been consistent with its philosophy based on professionalism and the capacity to evolve, enabling skills and resources to grow within the company while always maintaining focus on quality and confidentiality.

It is a concept that, over the years, has been able to combine high technology with superior manual finishing skills.

This is the guideline that has enabled G&G Composites to constantly grow in numbers and turnover, up to becoming a partner, and not just simple supplier, for national and international customers and continue a series of historic collaborations with important names in the world of auto racing, such as Dallara.

VALUES

- CONFIDENTIALITY

- PROFESSIONALISM

- PUNCTUALITY

- INNOVATION

STRATEGIES

- RECRUITMENT OF PROFESSIONAL STAFF

- INVESTMENTS IN INNOVATION AND TRAINING

- MEASURED COMPANY GROWTH

FACILITIES

G&G Compositi is an organized structure that covers over 1000 m2 where all the stages of production and component processing are carried out under constant monitoring.

The main plant measures 750 m2 and houses most of the manufacturing phases. Another 250-m2 facility was later added and is dedicated entirely to workstations that carry out both in-house production and special manufacturing to order.

San Pietro Mosezzo Plant

- 2 Climate-controlled clean rooms

- 1 Cutting room with cutting plotter

- 2 1000×2000 and 1300×3000 autoclaves

- 2 Ovens: one 3000×2500 equipped with vacuum pump and one 1000×1000

- 1 Dedicated 30-m2 finishing room with exhaust fans

- 1 Machine room (drills, presses, sanders, etc.)

- 1 Room for cold resin production

- 1 Quality Control room

- 2 Climate-controlled material storage room

- 1 Design and prototype room

Nibbia Plant

- 1 3-axis milling machine workstation

- 1 5-axis milling machine workstation

- 1 1200×2020 CNC 3-axis pantograph for cutting carbon fiber

- 1 100×2000 CNC 3-axis pantograph for machining polystyrene, PVC and by-products

DESIGN

Where it all starts. This is the first step of the project preparation stage, which can be studied in house at G&G Compositi or in cooperation with the customer’s design department.

This phase is crucial for guaranteeing a good design in which all our experience is put into optimizing the project and productive performance, with special attention to safety.

In this stage the role of G&G Compositi is essential, as we focus on the customer’s needs in order to always be a step ahead of problems with cutting-edge technical solutions.

In fact, components manufactured for the Racing sector (auto, motorcycle and boat races) must comply with the strictest impact-resistance and mechanical stress requirements, while staying within the specific weight limits imposed.